Reel cables are essential for delivering electrical power or control signals to motors and dynamic power systems. Proper cable selection is critical to ensure reliable operation, prevent downtime, and maximize equipment lifespan. Choosing the wrong reel cable can lead to overheating, voltage drops, premature failure, and safety hazards.

This comprehensive guide explains how to match reel cables to motor and power system requirements. Topics include cable construction, conductor sizing, insulation materials, bending radius, environmental considerations, and installation best practices. Engineers, technicians, and facility managers can use this guide to make informed decisions for industrial, commercial, and mobile applications.

A reel cable is a flexible cable wound onto a reel, designed to extend and retract safely while maintaining continuous power or signal transmission. Unlike stationary cables, reel cables experience mechanical stress, including bending, torsion, and tension, every time they are deployed or retracted.

High-quality reel cables provide:

Durability: Resistance to mechanical wear, abrasion, and environmental factors

Flexibility: Suitable for repetitive winding and unwinding cycles

Electrical reliability: Maintains voltage and current capacity under motion

Safety: Prevents short circuits, overheating, and equipment damage

Matching the cable to the specific motor or power system is vital for optimal performance and longevity.

Several factors must be considered when selecting a reel cable for a motor or power system:

Ensure the cable’s voltage rating meets or exceeds the system voltage to prevent insulation breakdown and potential fire hazards.

High-voltage motors require cables with thicker insulation and robust shielding.

Calculate the maximum current your motor or power system draws.

The conductor cross-section must be sufficient to handle continuous load without overheating.

Consider derating factors if cables are bundled or operate in high-temperature environments.

AC motors may require different insulation or conductor designs than DC systems due to alternating current effects and harmonic content.

Shielding requirements may vary based on signal integrity needs for control systems.

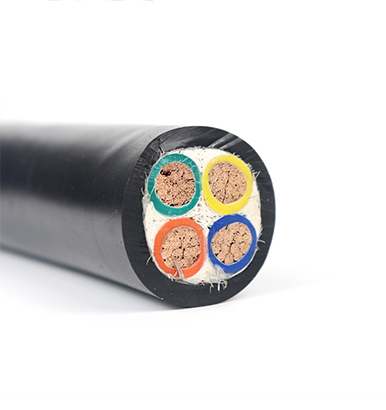

Copper is the most common conductor due to high conductivity and flexibility.

Aluminum is lighter but requires a larger cross-section for equivalent performance.

Fine-stranded conductors increase bending cycles without fatigue, essential for dynamic applications.

Multi-layer stranding helps reduce torsional stress during winding and unwinding.

Choose insulation that withstands voltage, temperature, chemical exposure, and mechanical stress.

Common options: rubber, polyurethane, thermoplastic elastomers.

Outer jackets protect against abrasion, moisture, UV, and chemical exposure.

Polyurethane jackets are ideal for high-cycle, industrial applications.

PVC jackets are suitable for indoor, light-duty applications.

Ensure the cable and reel maintain the minimum bending radius recommended by the manufacturer.

Exceeding this radius accelerates conductor fatigue and insulation cracking.

Torsional strain can damage conductors in rotating reels.

Use tension-controlled or motorized reels for heavy or long cables.

High-cycle motors require cables that maintain flexibility after thousands of bending cycles.

Braided or reinforced jackets can improve longevity in repetitive applications.

Reel cables may operate in harsh conditions depending on the application:

High temperatures can soften insulation; low temperatures can make cables brittle.

Polyurethane and rubber maintain flexibility across wide temperature ranges.

Outdoor or industrial installations may require water- and oil-resistant cables.

Check chemical compatibility with oils, solvents, and cleaning agents.

Outdoor systems should use UV-resistant jackets.

Abrasion-resistant jackets prevent damage from pulley guides or reel surfaces.

Determine voltage, current, and phase type.

Consider startup current, duty cycle, and power factor.

Evaluate whether the motor operates continuously or intermittently.

Use electrical formulas or tables to calculate cross-sectional area based on maximum current.

Include derating factors for ambient temperature, cable bundling, and insulation type.

Ensure the conductor size aligns with reel and reel guide limitations.

Match insulation to voltage rating and mechanical stress.

Choose outer jacket material for environmental conditions, abrasion, and chemical exposure.

Consider fire-retardant or halogen-free options if required by regulations.

Ensure the reel’s diameter and design maintain the cable’s minimum bending radius.

For high-current systems, verify that the reel’s mechanical strength can support cable weight.

Check tension control mechanisms to prevent conductor stretching or insulation damage.

Ensure voltage drop is within acceptable limits for motor operation.

Confirm that cable length does not compromise signal or power delivery.

Consider shielding for sensitive control or communication signals.

Avoid sharp bends and twisting during deployment.

Secure cable to prevent snagging or abrasion.

Align reel guides and rollers for smooth operation.

Test the system under load before full operation.

Routine maintenance extends cable life and ensures consistent performance:

Visual inspection: Check for cracks, fraying, or insulation damage.

Cleaning: Remove dust, oil, or chemical residues.

Tension checks: Adjust spring or motorized reels for smooth retraction.

Electrical testing: Periodically test continuity and insulation resistance.

Replace worn components: Avoid catastrophic failures by addressing early signs of wear.

Solution: Ensure conductor size and insulation match current load and temperature conditions.

Solution: Use fine-stranded conductors and maintain minimum bend radius.

Solution: Select abrasion-resistant jackets and guide cables properly on reels.

Solution: Optimize conductor size and minimize cable length where possible.

High-Speed Motors: Require cables with low inductance and capacitance for efficient power delivery.

Control Systems: Shielded or twisted pairs prevent electromagnetic interference in sensitive applications.

Long Cable Runs: Account for resistance, voltage drop, and potential power loss.

Environmentally Sensitive Installations: Use halogen-free or flame-retardant jackets for safety compliance.

A high-cycle crane system requires 50 meters of Flexible Reel Cable delivering 400V AC to a motor. By matching conductor size to peak current, selecting polyurethane insulation for abrasion resistance, and using a spring-tensioned reel to maintain bend radius, the installation achieves over 100,000 bending cycles with minimal wear. Regular inspection ensures continuous safe operation without downtime.

Matching reel cables to motor or power system requirements is a critical step for safe, efficient, and reliable operation. Key factors include:

Electrical ratings (voltage, current, phase, and duty cycle)

Conductor size, stranding, and material

Insulation and jacket properties for mechanical and environmental protection

Reel compatibility, bend radius, tension, and torsion considerations

Installation and maintenance best practices

Proper design and selection prevent downtime, reduce maintenance costs, and enhance system safety.

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)